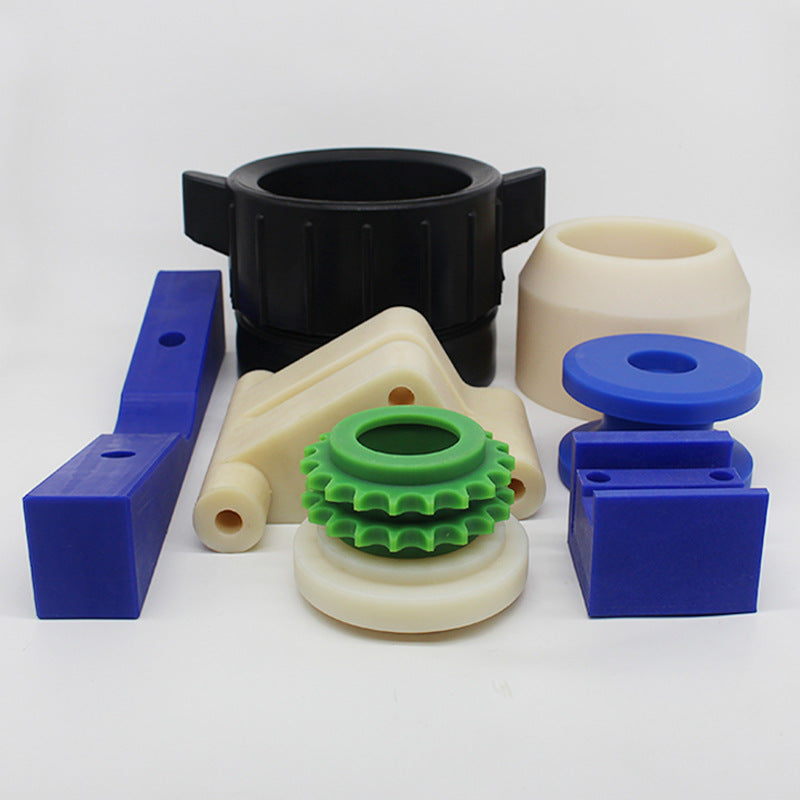

Nylon special-shaped parts plastic parts

Nylon special-shaped parts plastic parts

Tidak dapat memuat ketersediaan pengambilan

Chinese nylon plastic parts occupy a key position in the manufacturing industry due to their excellent performance, diverse molding processes, and wide range of applications. The following is a detailed introduction:

Performance Characteristics:

High Strength and Toughness: Nylon plastic parts possess high tensile strength and impact toughness, capable of withstanding certain external forces and impacts without breaking. They are used in the manufacture of load-bearing components, such as mechanical gears and automotive drive shafts.

Good Wear Resistance: Their excellent wear resistance and low coefficient of friction reduce wear between components and extend service life. They are commonly used in the manufacture of wear-resistant components such as bearings and sliders.

Strong Corrosion Resistance: Nylon plastic parts exhibit excellent resistance to many chemicals, including acids, alkalis, and salts. They are suitable for components operating in harsh chemical environments, such as pipes and valves in chemical equipment.

Good Temperature Resistance: Nylon plastic parts exhibit a certain degree of heat and cold resistance, allowing them to be used over a wide temperature range. Some nylon plastic parts can operate for extended periods in environments above 100°C and maintain good toughness even at low temperatures, preventing brittle cracking. Molding Processes:

Injection molding: This is the most commonly used molding method for nylon plastic parts. Nylon pellets are heated and melted, then injected into a mold cavity. After cooling and solidification, the desired shape is achieved. This process offers high production efficiency and is suitable for mass production. It can produce plastic parts with high dimensional accuracy and excellent surface quality, such as electronic device housings and automotive interior trims.

Extrusion: This is primarily used to produce continuous-form products such as nylon tubing, rods, and profiles. After heating and melting the nylon raw material, it is forced through the extruder's screw and extruded through a specifically shaped die. After cooling and setting, the product is widely used in areas such as construction pipes and mechanical transmission profiles.

Blow molding: This is commonly used to manufacture hollow nylon containers, such as plastic bottles and fuel tanks. A heated nylon preform is placed in a mold, where compressed air is blown in to expand it to fit the mold walls. After cooling, the product is formed. This process offers advantages such as high production efficiency and uniform wall thickness. Application Areas:

Automotive Industry: Nylon plastic parts are widely used in automobiles, such as engine peripheral components. Leveraging their heat and oil resistance, they can be used to manufacture intake manifolds, oil pans, and other components. They are also used in automotive interior components such as seat frames and instrument panel housings. Their lightweight properties reduce vehicle weight and improve fuel economy.

Electronic and Electrical Industry: With their excellent insulation and mechanical properties, nylon plastic parts are used in the manufacture of housings, terminal blocks, switches, and other components for various electronic devices, providing protection and support for electronic components while meeting electrical insulation requirements.

Machinery Manufacturing Industry: Nylon plastic parts can replace some metal parts in the manufacture of transmission components such as gears, worm gears, and worms, as well as wear-resistant parts such as bearings and guide rails, reducing costs while also reducing friction and noise.

Aerospace Industry: Due to their lightweight and high strength, nylon plastic parts are used in the manufacture of aircraft interior components such as seat components, luggage racks, and ventilation ducts, helping to reduce aircraft weight and improve fuel efficiency and flight performance.

Current Development Status: China's nylon plastic parts industry is developing rapidly, with numerous production companies primarily concentrated in the Yangtze River Delta, Pearl River Delta, and Beijing-Tianjin-Hebei regions. With the continuous advancement of technology, domestic companies have achieved remarkable results in nylon material modification and molding process optimization. The continuous improvement of product quality and performance not only meets the needs of the domestic market, but also gradually enters the international market. At the same time, to meet environmental protection requirements and high-end application needs, biodegradable nylon plastic parts and high-performance and high-precision nylon plastic parts have become research and development hotspots, driving the industry towards green and high-end development.